|

| October 16, 2012 | Volume 08 Issue 39 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Caterpillar plant links 77 diverse manufacturing assets for real-time monitoring, OEE gains

Real-time information from Freedom eLOG software on the performance of 77 diverse manufacturing systems at Caterpillar's Integrated Manufacturing Operations Division (IMOD), Aurora Facility (Aurora, IL), is helping the operation increase overall equipment effectiveness (OEE), reduce cost, improve processes, and shorten maintenance response times.

The eLOG software -- developed, installed, and supported by MAG -- makes real-time factory asset performance transparent, enabling rapid implementation of operational and maintenance excellence, according to Tom Abens, strategic planning supervisor for lower powertrain at IMOD Aurora. "There is no doubt it is helping us improve the efficiency and competitiveness of our plant," he says. "We have improved the performance of virtually every asset, with average gains of 21%."

Caterpillar's Aurora plant started with an early version of eLOG on some MAG horizontal machining centers in 2007 and worked with MAG to guide the software's development and broaden its application. "Our original goal was, and remains, single-point access to information on the performance of all critical assets," says Abens. "The big challenge is connectivity, because of the diversity and age of our plant equipment. We have many generations and makes of CNC controls, some brand new and some decades old."

The Aurora plant currently has 77 assets being monitored by eLOG and plans to increase that to 95. The systems include horizontal boring mills, gantry machining centers, robotic welding cells, induction scanners for heat treating, gear-cutting machines, lathes, and miscellaneous machining centers. "Some of these systems are critical and must have very high efficiency and availability, such as the boring mills that machine an engine frame complete," says Abens.

eLOG is designed for exactly this situation. eLOG is one module of a larger software suite named eWARE, which is compliant with AMT's MTConnect communications protocol. eLOG can collect data from CNC or non-CNC equipment without modification to ladder logic or part programming.

The software's control-resident eCONNECT interface runs on each machine that uses a PC front-end control. For non-PC-based CNC's, PLC's and manual machines, the software uses a hardware bridge to make discrete I/O connections to specific machine electrics. eCONNECT is the data collection hub and access point for equipment on the plant floor, while it supplies information to eLOG. "MAG easily networked assets that had been an obstacle for us in the past," said Abens. "The company's diverse awareness of factory floor processes is also helpful in implementing the software."

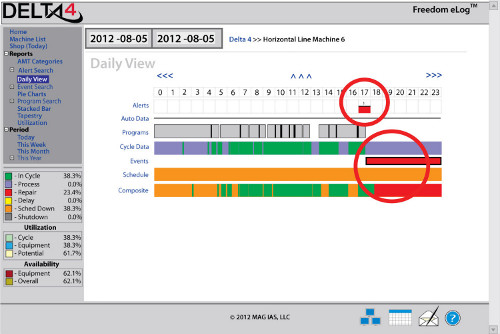

eLOG uses algorithms based on AMT and VDI standards to categorize time into six different areas: Plant Shut-Down, Scheduled Downtime, Delay Time, Repair Time, Not-In-Cycle Process Time and In-Cycle Time. Reports available in eLOG include: top 25 alerts, top 25 events, top 25 programs by duration or by count, a daily view of activity over a 24-hour period, OEE and a tapestry report for day-by-day or hour-to-hour comparisons. eLOG allows rapid visualization of inefficiencies and identification of root causes to facilitate mistake-proofed processes, improved utilization, condition-based maintenance and reduced MRO inventories. Information can be formatted and filtered for specific departments, such as production, planning or maintenance. The software can also send text and email alerts.

The Daily View screen in eLOG provides a 24-hr snapshot of asset activity, condition, and alerts.

"Freedom eLOG has helped us isolate the root causes of downtime on assets, rather than speculate about them," explains Abens. "It certainly improved our maintenance response times and allocation of resources. We have been able to identify recurring maintenance issues that needed a different solution. We have been able to identify and correct small inefficiencies in processes that we thought were performing at high levels. Most importantly, we have been able to avoid capital expenses for new manufacturing assets by increasing our OEE. In other cases, we identified and justified the need for new assets. We have made great strides, but this is only the beginning.

"Freedom eLOG information is comprehensible for all levels of employees, and while the information input is not 100% automated yet, it has been streamlined with bar code scanners and touch screens to simplify it as much as possible for machine operators," Abens adds. "We have good engagement from the shop floor to the top floor. We're currently accessing eLOG data on iPads and laptops inside our plant. Our high level of security prevents us from making the data accessible off campus. The eLOG dashboard is the first thing I look at every morning, and it's used by our plant management and beyond."

eLOG allows managers to view individual repair tickets created by machine operators on the shop floor.

eLOG is currently being implemented at Cat's Aurora, Joliet, and South Milwaukee plants, with plans in place for plants in East Peoria; Monterrey, Mexico; and Thiruvallur, India.

eWARE's full list of components includes: eLOG, eSCOPE, eMONITOR, eENERGY, eCONNECT, eMOBILE, and eCELL.

eWARE is certified as "networthy" for use by U.S. Department of Defense agencies, armed forces, and contractors. This certification ensures Automated Information Systems (AIS) utilizing the Army Network are developed in compliance with the Clinger Cohen Act and are secure, supportable, sustainable, and compatible with the Army Enterprise Infostructure (AEI) (as defined in AR 25-IA). The software provides multiple language support including: English, French, German, Italian, Korean, Portuguese, Romanian, Spanish, and Chinese.

For additional information on eWARE monitoring software, contact Pete Tecos, MAG executive vice president of global business development, at 586.202.3285 or email pete.tecos@mag-ias.com.

Source: MAG Industrial Automation Systems

Published October 2012

Rate this article

View our terms of use and privacy policy